See below for a more in-depth look at these capabilities.

Cable Assembly Capabilities

At MarVac Assemblies, our core cable assembly services include:

- Custom Wire Harness and Cable Assembly

- Cable Assembly Capabilities: Box Build Assemblies

- Cable Assembly Capabilities: Mechanical Sub-Assembly

- Cable Assembly Capabilities: Wire Processing

- Cable Assembly Capabilities: Soldering

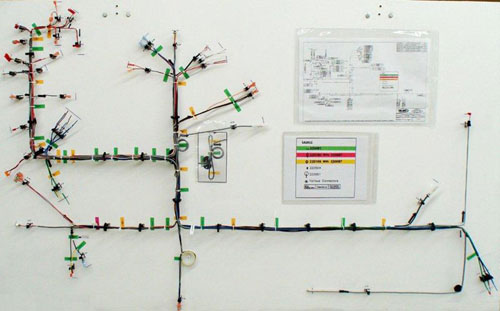

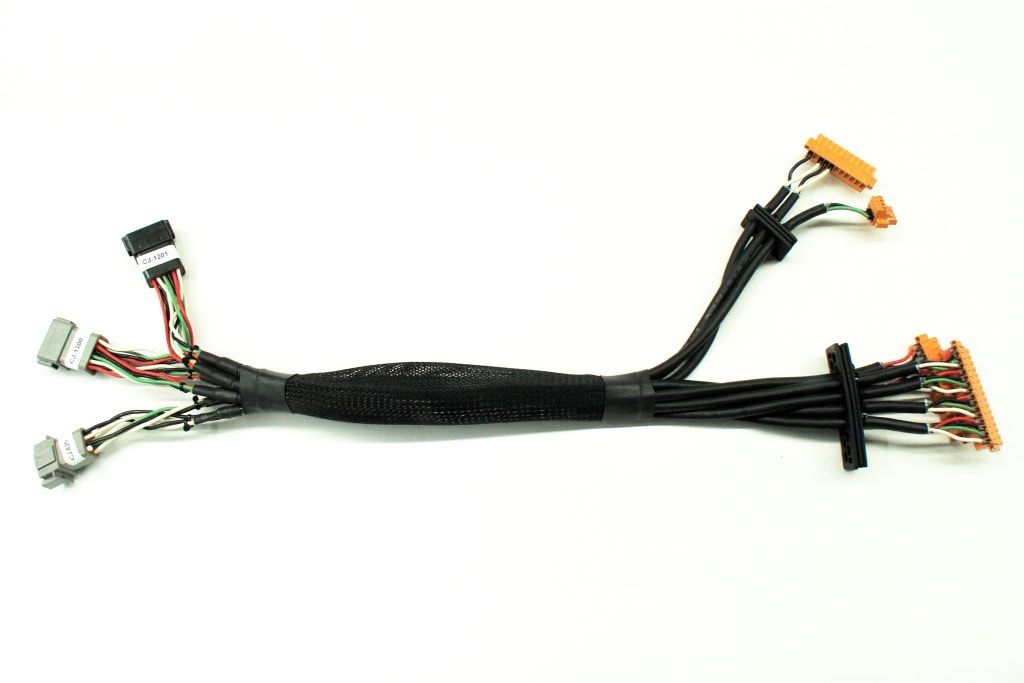

Custom Wire Harness and Cable Assembly

MarVac Assemblies can handle a wide assortment of stranded or solid wire with gauges ranging between 2 and 24 AWG. Our advanced custom wire harness assembly processing equipment meets all WHMA/IPC-A-620 industry standards.

Our assembly processes and equipment can be effectively applied to a range of assembled products, including but not limited to:

- Agricultural Equipment Electrical Systems

- All Terrain Vehicles Electrical Systems

- Appliance Electrical Systems

- Electrical System Assemblies

- Electrical Systems for Batteries

- Electrical Systems for Engines

- Gauges

- Heaters

- Lighting Fixtures

- Mechanisms for Electrical Systems

- Motors

- Off-Road Vehicle Battery Systems

- Power Tool Electrical Systems

- Refrigeration Equipment

- Welders

Cable Assembly Capabilities: Box Build Assemblies

Our panel assembly and box build services are compatible with a broad range of products for many diverse industries. By performing manual assembly operations, such as drilling and riveting, we can handle complete box builds and sub-assemblies, including fuse boxes, wiring to fuse boxes, and terminal blocks. We can attach connector ends to the wiring and install them inside a panel. Additionally, we can utilize pneumatic hand tools for some assembly operations.

Common applications of our box build assemblies include the following:

- Connector Ends

- Control Panels

- DIN Rail Racks

- Fuse Blocks

- PLC Assemblies

- Push Buttons

- Relays

- Terminal Blocks

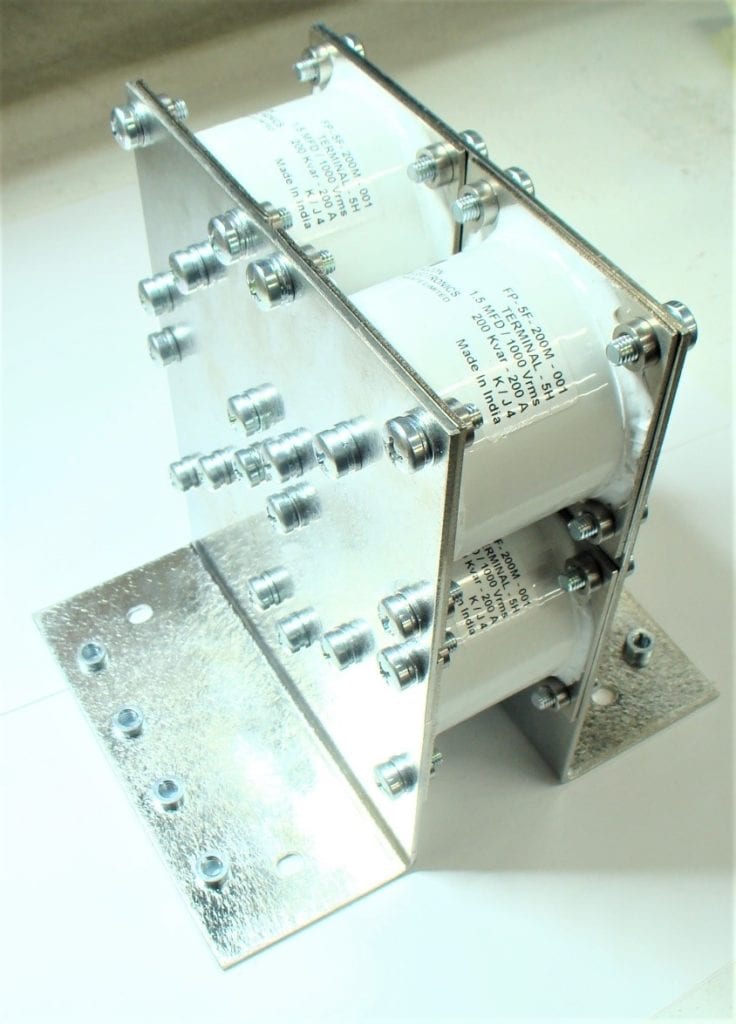

Cable Assembly Capabilities: Mechanical Sub-Assembly

At MarVac Assemblies, we offer mechanical sub-assembly services with capabilities that include but are not limited to the following:

- Capacitors

- Cooling Fans

- Circuit Protection Components

- Solenoids

- Terminal Block

- Wire Wound Resistors

We strive to provide exceptional custom electromechanical assembly services with on-time delivery for every project. Similarly to our other production services, we can work with a range of solid and stranded wires, ranging from 22 to 000 AWG.

Specializing in OEM electronic sub-assemblies, terminating transfer wires, and soldering, the experts at MarVac Assemblies provide superior box build and bench top sub-assembly construction using authorized electronic components specified by our customers. We have a long and successful history serving a wide variety of industries, including food and beverage, general industrial, medical, transportation, instrumentation, and self-service banking.

Cable Assembly Capabilities: Wire Processing

MarVac Assemblies’ custom wire processing equipment works with various types of insulated wires, and our custom cable assemblies can accommodate stranded or solid wire with gauges ranging between 2 and 24 AWG.

Our top-quality custom wire processing equipment and wiring harness services meet all WHMA/IPC-A-620 industry standards. Our assembly processes and cutting-edge equipment can be used for various applications, including:

- Electrical System Assemblies

- Heaters

- Lighting Fixtures

- Off-Road Vehicles

- Printed Circuit Boards

- Power Supplies

- Refrigeration Equipment

- Welders

MarVac Assemblies can work with PVC, rubber, silicone, and Teflon materials, and we have the following wire processing capabilities:

- Crimping (2AWG to 24AWG)

- Cutting of Wire (6AWG to 32AWG), Including Multi-Conductors

- Flat Cable to Conductors

- Marking of Wire (6AWG to 32AWG), Including Multi-Conductors

- Wire Twisting (14AWG to 24AWG)

- Strip and Retain

- Terminating Ends

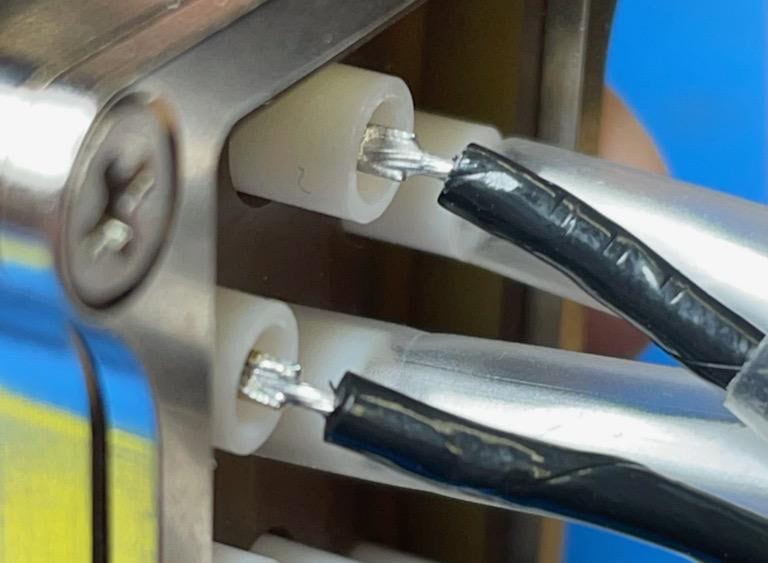

Cable Assembly Capabilities: Soldering

MarVac Assemblies specializes in providing sonic weld and mechanical soldering services, with capabilities that include the following:

- Display Soldering Operations

- Wire to Board

- Wire to Component

- Wire to Connector

- Wire to Resistors

Our dedicated soldering cells work exclusively with copper material and come equipped with individual exhaust ducting. We work with a broad range of OEM suppliers and professional industries, helping them to realize innovative manufacturing solutions that facilitate lean production standards for improved products at reduced costs. We also offer design suggestions that help to improve product manufacturability.

Outsourcing Cable Subassemblies

Outsourcing your cable subassemblies may seem like an expensive choice; however, it offers many benefits that outweigh the initial costs. For example, outsourcing your cable subassemblies provides a way to streamline and simplify production while ensuring faster and more efficient project completion.

At MarVac Assemblies, we deliver quick turnaround and on-time delivery for every project. Once we understand your unique subassembly needs, we’ll handle everything from parts procurement to final assembly, allowing our customers to focus on other areas of their business while benefiting from our expert capabilities.

Cable Assembly Capabilities and Services from MarVac Assemblies

Cable and wire assemblies play a critical role in ensuring the flow of data, power, and signals between different equipment and machinery. At MarVac Assemblies, we have over 75 years of experience providing various cable assembly services for customers across diverse industries. Regardless of your needs, we can work with you to develop a completely customized cable assembly solution for your application.

For more information about our custom cable and wire assembly capabilities, contact us or request a quote today.